Manufacturing Solutions

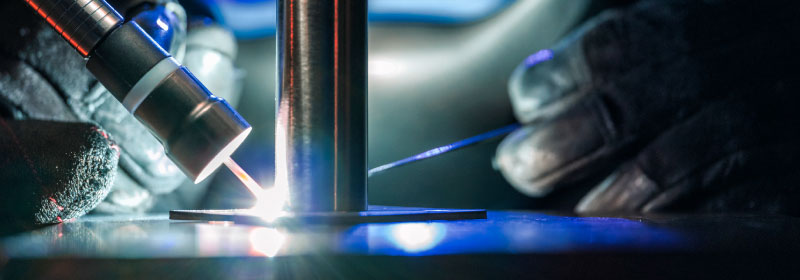

While Schivo operates a state-of-art precision manufacturing system, it is the unconventional way it applies the system that achieves breakthroughs in OEM cost, productivity, and time to market.

We extract value from our global facilities that goes beyond manufacturing to maximize customer profit and improve the patient experience.

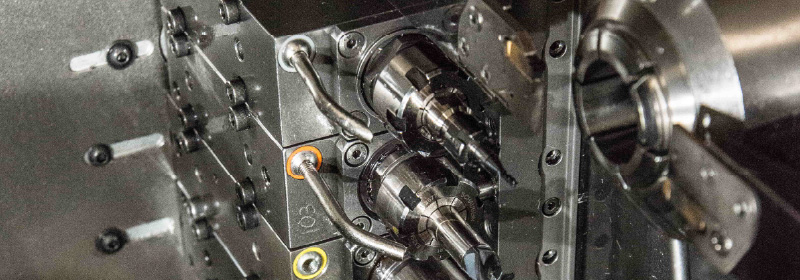

Our vertically integrated manufacturing platform combines best-practice NPI, precision machining, overmolding and injection molding, and packaging and logistics to create a value chain that extracts cost and time from the production cycle.

With its deep expertise, Schivo has transformed its Swiss machining equipment into multi-processing work centers that offer a virtually unlimited range of manufacturing capabilities. At Schivo, one machining center can manufacture a component that would traditionally require four or five machines to produce. This unique machining knowledge drives Schivo to develop unconventional approaches that achieve breakthroughs in cost and production time.

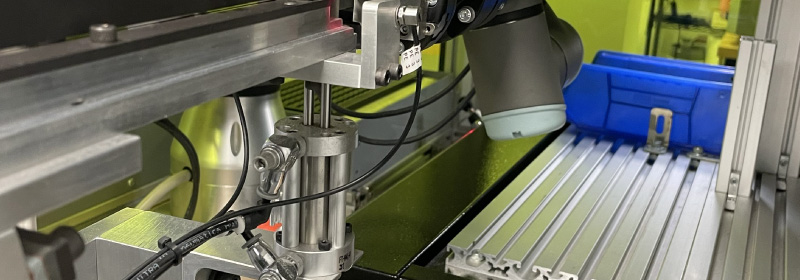

Schivo’s data collection and tracking methodologies are key elements in its world-class quality system.

Every part’s quality history is continuously recorded to ensure it meets or exceeds OEM specifications.

Schivo offers a wide range of capabilities across a global production system that includes 630 employees at eight facilities with a total of 302,000 square feet of manufacturing space. These facilities are ISO 13485-certified and FDA-registered. Plus, we operate ISO Class 7 and 8 electro-mechanical clean rooms.