Product Capabilities

Schivo’s unconventional approach to creating value on its best-practice manufacturing system has created a wide range of robotic-assisted and minimally invasive surgery products.

We extract value from our global facilities that goes beyond manufacturing to maximize customer profit, reduce times to market, and improve the patient experience. Schivo’s non-traditional thinking exceeds the limitations of conventional methods to help ensure the best cost and elimination of risk for the OEM customer across the contract manufacturing process.

We are determined not to accept the limitations of common or customary solutions in creating and manufacturing our products. This company culture drives us to engage in intense problem solving and create greater efficiencies with our tools, people, and knowledge.

Schivo’s large portfolio of ultra-high-quality custom components, sub-assemblies, and assemblies includes:

Analytical probes: these specialized tools analyze tissues, fluids, or physiological parameters in real time. Schivo’s ultra-high-quality probes help surgeons make more informed decisions during procedures, especially in minimally invasive or robotic-assisted surgeries.

Vessel cutters: these precise surgical instruments cut blood vessels during medical procedures. They are commonly used in minimally invasive surgeries, especially in cardiovascular, neurosurgical, and robotic-assisted procedures. Schivo produces integrated vessel cutting tools with enhanced precision for the world’s leading robotic-assisted surgery systems.

Cannulas: Schivo’s cannulas are thin, flexible tubes inserted into the body to deliver or remove fluids, gases, or surgical instruments.

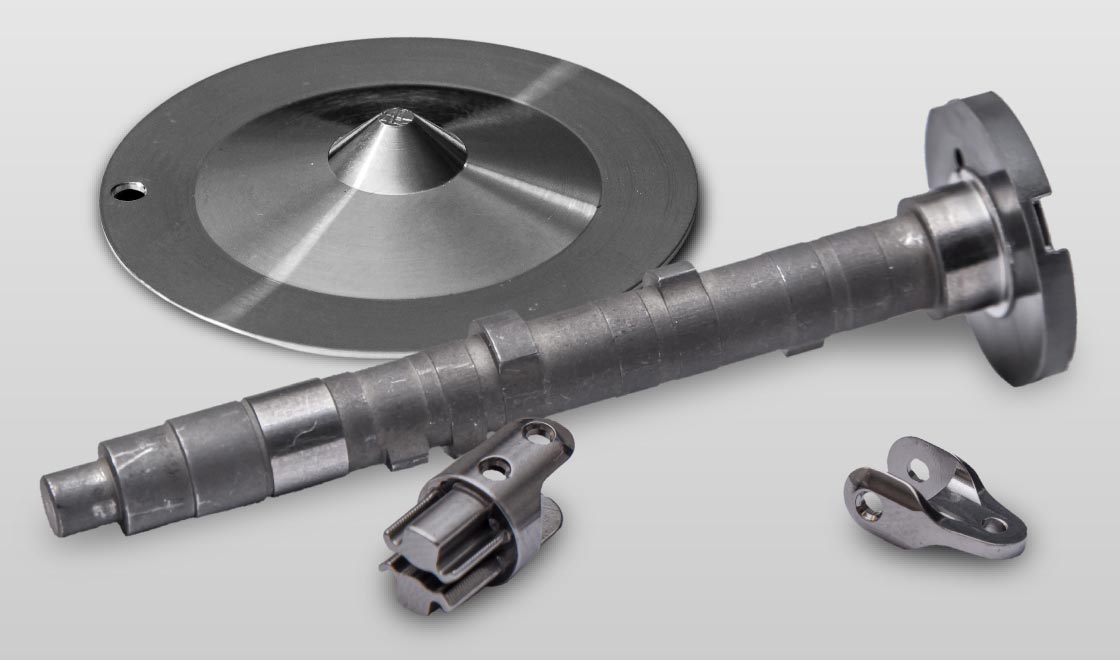

Trocars: a sharp-pointed, often tubular instrument, the trocar is used to create access ports during minimally invasive surgeries like laparoscopy or endoscopy. They allow the insertion of surgical tools or cameras into body cavities. Schivo’s trocars maintain a sealed environment, particularly in procedures involving insufflation.

Surgical introducers: these medical instruments facilitate the insertion of other surgical devices—such as catheters, guidewires, or endoscopes—into body cavities, vessels, or organs with minimal trauma. Schivo’s introducers are widely used during laparoscopic or endoscopic surgeries to create a port of entry.

Dispensing tips: Schivo’s dispensing tips are precise components used to accurately apply or dispense fluids like adhesives, sealants, glues, lubricants, or medications during surgical procedures. They are often used with syringes or dispensing systems for controlled application in sterile environments.

Electro-surgical components: these products are found in electrosurgery devices that use high-frequency electrical currents to cut tissue and coagulate blood vessels. Schivo’s components are widely used in general surgery and minimally invasive procedures.

Endoscopic scissors: these specialized surgical instruments are used during minimally invasive (endoscopic or laparoscopic) procedures to precisely cut tissue, sutures, or other materials inside the body through small incisions. They are introduced into the body through trocars or cannulas and manipulated via a long shaft from outside the patient. Schivo’s products have ergonomic handles for precise instrument control.

Filling needles: surgical filling needles are specialized instruments used in various surgical applications to deliver or transfer substances into tissues, cavities, or other medical devices. Schivo’s highly precise needles are designed to inject or fill biological materials, adhesives, cements, or other medical compounds into targeted areas during orthopedic procedures.

Knife assemblies: these complete systems or kits, which include a surgical blade, handle, and additional components, are designed for precise cutting during surgical procedures. Schivo’s knives are precision machined of surgical steel with ergonomically designed handles for comfort and control.

Hypodermic tubes and sharpened tubes: thin, hollow hypodermic tubes are used in medical and surgical procedures for delivering or withdrawing fluids. They are usually connected to a hypodermic needle or syringe. Schivo’s sharpened tubes can be customized with sharp or tapered ends to facilitate insertion in procedures like endoscopy.

Surgical blades and medical blades: these precision-machined cutting tools are used in medical procedures to make incisions or excisions. They are usually attached to a scalpel handle and come in various shapes and sizes depending on their use.

Interventional cardiology catheters: Schivo fabricates and assembles these highly specialized, minimally invasive devices used to diagnose and treat heart and vascular conditions. Our catheters meet rigorous performance, biocompatibility, and regulatory standards. They are sized precisely for fluid or device passage and are tailored to navigate challenging vasculature.

Dental prophylaxis instruments: common tools used in preventative dental care, Schivo makes products with a blend of precision engineering, biocompatible materials, and strict regulatory compliance.

Medical connectors: Schivo’s best-practice injection molding and overmoldng capabilities produce secure, sterile, and reliable connections between medical devices, tubing, and electronic systems.

Medical pumps: these products require extremely tight microfluidic tolerances that are tailor-made for Schivo’s micro-injection molding of small, high-precision plastic parts. We produce components with leak-free fluid paths and our cleanroom assembly assures contamination control.

Gynecological applicators: Schivo’s injection molding and overmolding processes are ideal for manufacturing body and plunger components and applicator tips.

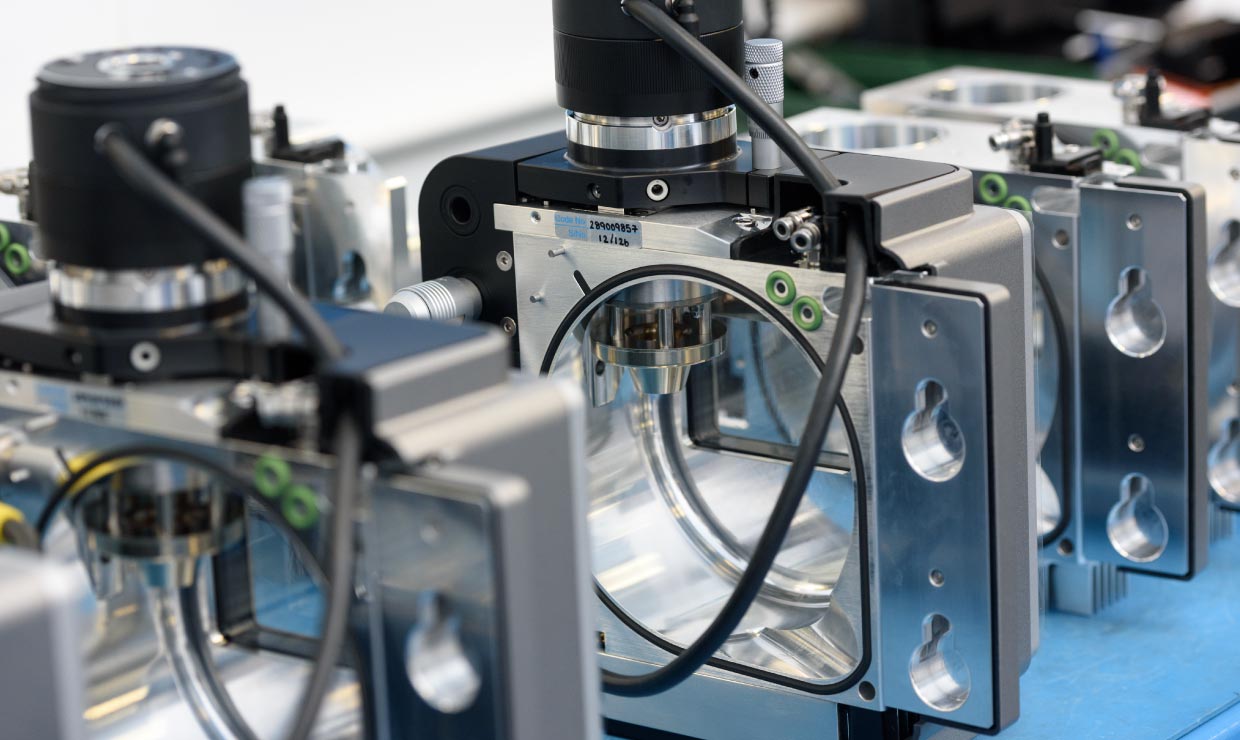

Complex sub-assemblies: Schivo is a specialist in producing intricate sub-assemblies and modules for medical devices. These include miniature optical systems and articulating mechanisms for endoscopic systems, and actuator assemblies and sensors for robotic surgery equipment.

Finished medical devices: when developing new medical device technology, seamless sub-assembly integration is extremely important for final assembly. Schivo’s value goes far beyond the precision machining of components. We have a deep understanding of how sub-assemblies work together, and the required steps to assemble a complete device. We provide a project financial structure that ensures a competitive OEM product and assures that patients receive an effective device or procedure that insurers will reimburse.