Post Processing

Schivo’s post-processing capabilities involve a series of finishing steps applied after the primary manufacturing or forming of a component. These steps enhance performance, ensure biocompatibility, comply with regulatory standards, and prepare the part for final assembly or sterilization.

Schivo’s post-processing capabilities include:

Analytical cleaning: Schivo scientifically validates processes to ensure that medical devices are free from contaminants—such as residues from manufacturing, cleaning agents, lubricants, or biological material—before they are packaged, sterilized, or used clinically. This step is critical for patient safety and regulatory compliance.

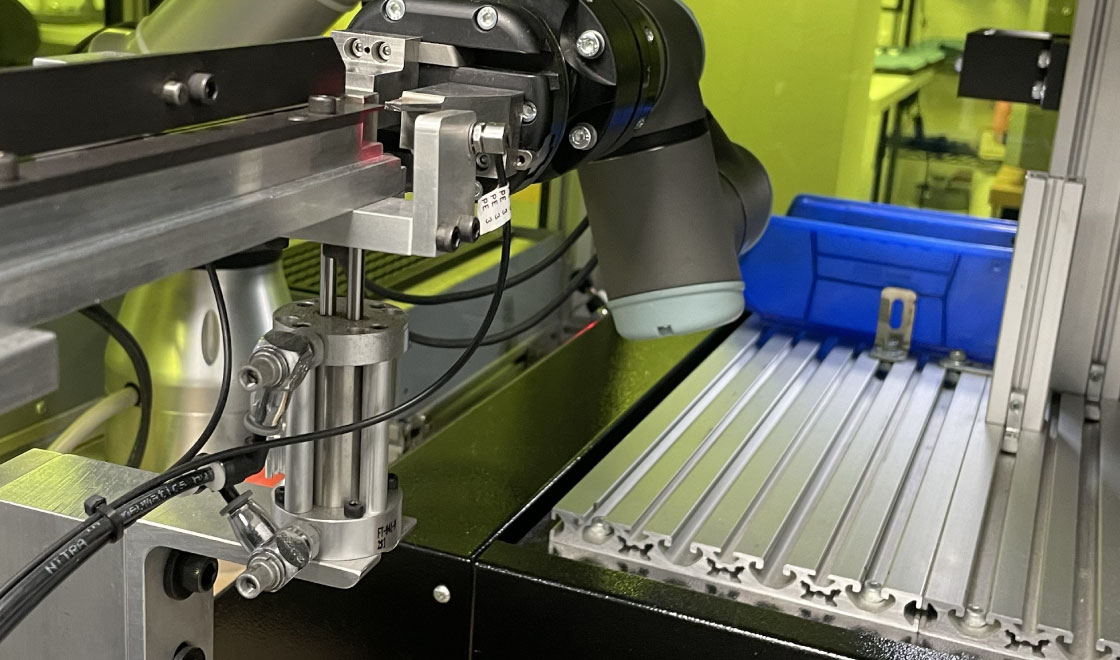

Deburring and turning: These processes play an important role in the manufacturing of precision components for surgical instruments and implants. Schivo’s robotic deburring and buffing processes remove sharp edges, burrs, or residual material left from machining processes to ensure safety, performance, and compliance. Our turning process shapes cylindrical or rounded components with high accuracy and precision.

Blasting: an important surface treatment in component post-processing, Schivo’s process involves propelling abrasive materials at a device surface to clean, texture, or prepare it for further treatments (such as coating, bonding, or sterilization).

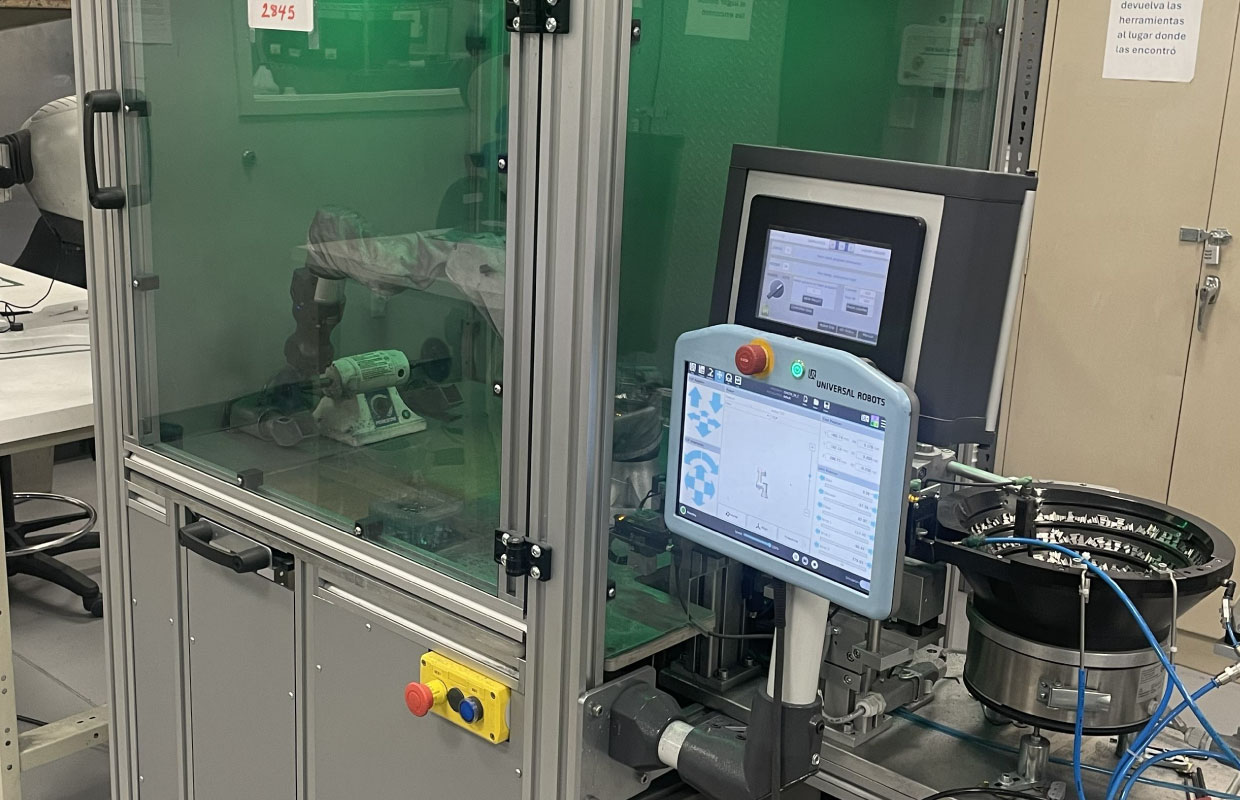

Automated lapping: Schivo’s precision surface finishing process achieves extremely tight tolerances, smooth surface finishes, and component flatness. Our automated lapping delivers consistent results, higher throughput, and better process control.

Automated polishing: our precision surface-finishing process enhances the smoothness, cleanliness, and performance of components used in implants and surgical instruments. Schivo’s automated polishing ensures repeatability, tight surface quality tolerances, high productivity, and compliance with regulatory standards.