Overmolding

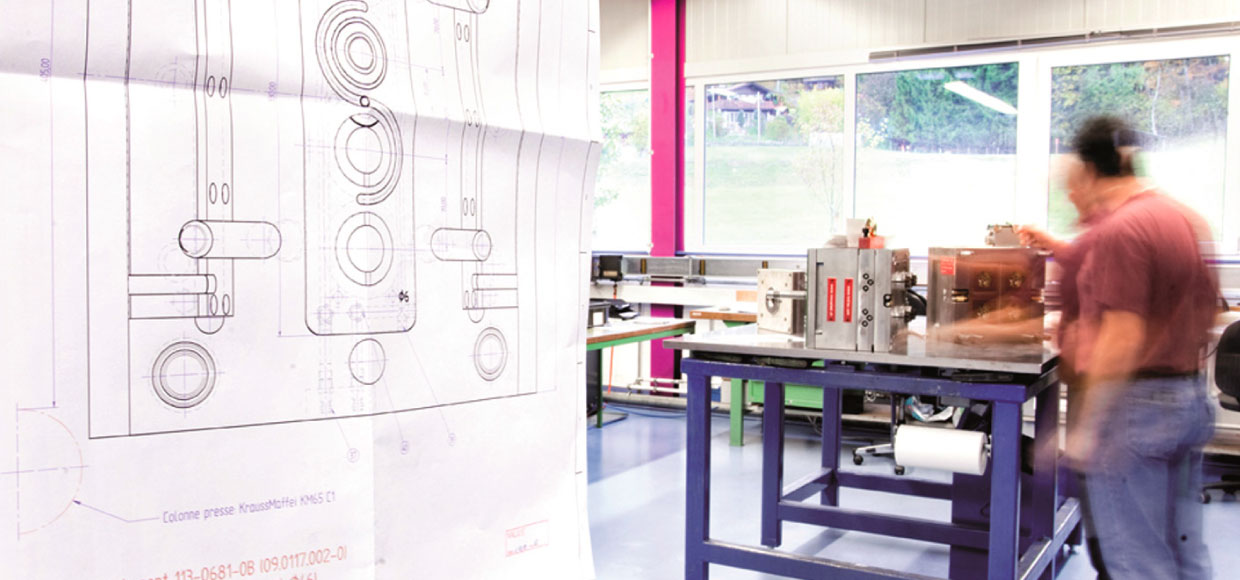

Schivo’s overmolding process is part of a comprehensive, vertically integrated solution that includes engineering, tooling development, molding processes, tool manufacturing, and maintenance. This unified set of services gives us total control over the entire process and production chain.

Schivo’s integrated approach offers customer key advantages:

- End-to-end control ensures consistency, quality, and traceability

- Rapid iteration and optimization occur with all teams under one roof

- Fully customized solutions are tailored to each customer’s technical and operational needs

- Flexible manufacturing setups range from manual operations for small series or complex parts to fully automated lines for high-volume production

- In-house tooling allows fast adjustments and maintenance, reducing downtime and lead times

This level of integration enables Schivo to deliver a broad range of custom overmolded components with high-performance and cost-effectiveness — consistently and reliably.

Our overmolded products include:

- Interventional cardiology catheters

- Dental prophylaxis instruments

- Medical connectors

- Medical pumps

- Gynecological applicators

- Surgical instruments

- Robotic surgical instruments

Schivo’s overmolding operations are ISO 13485, ISO 14644, and ISO 9001 certified and FDA registered.