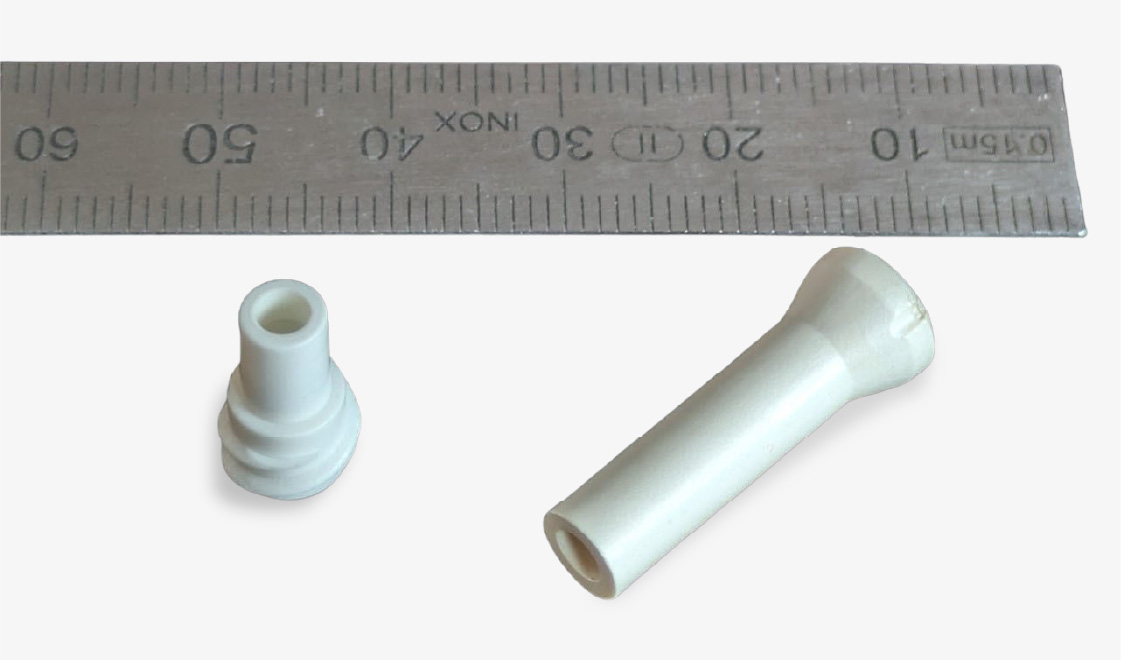

Ceramic Injection Molding

Schivo’s ceramic injection molding (CIM) capabilities produce complex, highly precise components that require wear resistance, thermal stability, and chemical inertness. Our in-house process incorporates injection molding, advanced ceramics, and sintering machines. Schivo’s extensive thermoplastics expertise includes technical, medical-grade, and implantable polymers. We process zirconium oxide (ZrO2) when the application requires tougher, stronger, implant-friendly qualities; and aluminum oxide (Al2O3) when less-expensive, harder, biocompatible, and insulating characteristics are specified.

Schivo’s CIM components provide the following benefits:

Biocompatibility: medical device parts are non-toxic, corrosion resistant, no metal ion leaching, and tissue friendly, making them ideal for implants and patient contact.

Wear resistance: ceramics last longer than metals, making them well suited for joint replacements, surgical mechanisms, and sliding interfaces.

Miniaturization and precision: the process enables tiny geometries, microfeatures, thin walls, and complex shapes without machining.

Sterilization resistance: there is no degradation as in plastics.

Schivo’s CIM process is an attractive option for surgical instruments and implants where complex, high-wear, corrosion-proof medical device components are required in medium to high volumes.

Manufacturing Capabilities

- More than 40 injection molding machines, including ISO Class 7 cleanroom operations

- Scalable production: from single prototype to high-volume manufacturing

- Multi-technology molding expertise, including silicone (LIM) and metal injection molding (MIM)

- Molded part precision: +/-0.03 mm

- Reprocessing CNC dimensions: +/-3 um, if necessary

- Weight 0.1 g to 50 g (ZrO2) and 0.1 g to 33 g (Al2O3)

- Production and validation lead times: 18-22 weeks