Working With Challenging Budget Restrictions

As an engineer, you know the triangle: cost, quality, and speed, choose any two. Schivo wants to give you a better balance between these engineering pillars; one producing enhanced results at lower costs. Also, Schivo makes it a point to scale up with our clients. As your business grows, and the demand for products with the components we produce increases, we expand production collaterally. You can always rely on our solutions, even as the environment you're managing transforms.

Quality and reliability build relationships. Accordingly, Schivo will work with all clients, but we don't exclude smaller ones. If we solve their problems, they do better. If they do better, their orders increase. If their orders increase, we do better; it's a positive feedback loop.

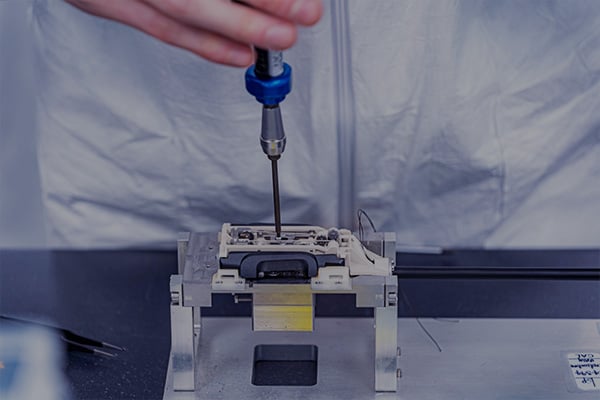

Our success is your success. We balance cost against functionality, capability, reliability, quality, and swift delivery of orders to specifications. Throughout the process, we communicate closely with you, and even invite you to visit our production floor to see our development in action.

Be the Engineering Hero of Your Company

Clients provide a design, we work with them to actualize that design practically. This requires ongoing communication. Each client represents a vested interest, and your best outcomes motivate our production. Thus, we get involved early and find that balance of time, cost, and quality.

As we reach solutions, we scale out to match transforming needs. Most of our work is done in-house for this reason, among others. You're not stratifying design across multiple outsourced facilities, you're working with one.

Schivo's pragmatism solves problems. We work with you transparently throughout the process to thwart budgetary restrictions coming from bean counter inexperience. We design components conducive to long-term manufacturing friendliness. We continue to work with you toward total refinement as our partnership grows.

Whether you need 100 pieces per order, 1,000, or 5,000, we'll work with you. If you're seeking to increase the velocity behind your engineering career trajectory, working with us might be the fuel mixture you've been looking for.