Our Facilities

Schivo operates a best-practice global manufacturing system that makes components and devices offering value beyond contract manufacturing to enhance OEM profit and save lives.

From quick prototypes to single parts to complex assemblies, our manufacturing organization manages the entire supply chain — providing ultra-high-quality solutions packaged, sealed, sterilized, and shipped to your distribution sites anywhere in the world.

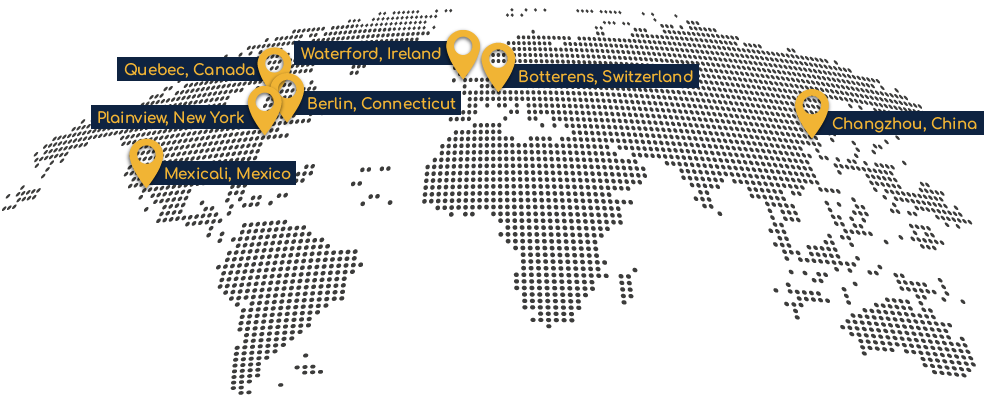

We cover the world with facilities in:

- Waterford, Ireland

- Plainview, New York

- Berlin, Connecticut

- Quebec, Canada

- Botterens, Switzerland

- Mexicali, Mexico

- Changzhou, China

These locations total 302,000 square feet of manufacturing space, employ 630 people, and are supported by more than 500 vendors. Our facilities are ISO 13485-certified and FDA-registered. Plus, we operate ISO Class 7 and 8 electro-mechanical clean rooms.

Our locations

Waterford, Ireland

115,000 sq. ft.

Corporate Headquarters

Schivo’s global headquarters and most comprehensive manufacturing facility, Waterford incorporates extensive CNC machining capacity, skilled operators, and a comprehensive range of vertically integrated processes under one roof. Its robust engineering and NPI organization accelerates development cycles and supports high-level system integration, including FDA-approved manufacturing lines for complete medical devices. ISO Class 7 and Class 8 clean rooms enable controlled assembly and sterile handling, strengthening time-to-market performance within the Schivo manufacturing platform

Plainview, New York

60,000 sq. ft.

One of the largest Tornos sliding-head Swiss machining installations in the United States, the Plainview facility leverages decades of expertise to deliver world-class value. The team applies deep process knowledge and optimization-driven programming to maximize machine capability and reduce cycle times — enabling precise, cost-effective components and assemblies. Supported by a robust ISO 13485–aligned quality management system with full traceability, Plainview provides reliable production through finishing, packaging, and logistics within Schivo’s vertically integrated platform.

Quebec City, Canada

60,000 sq. ft.

This state-of-the-art manufacturing facility leverages Industry 4.0 systems to produce highly precise, repeatable CNC machining at scale. With deep expertise in downstream processes —including component cleanliness, advanced assembly, functional testing, and qualification — Quebec City supports demanding regulatory and performance requirements. Digitized process control and traceability provide exceptional quality assurance while enabling seamless progression from prototype to serial production and integration across Schivo’s global network.

Mexicali, Mexico

25,000 sq. ft.

Launched in 2025, Mexicali is a greenfield manufacturing facility that supports scalable, cost-competitive growth for Schivo’s global customers. The site delivers advanced CNC machining and precision assembly of high-level mechanical systems with infrastructure designed for rapid expansion. As the site matures, molding, overmolding onto machined metallic components, and secondary finishing processes — including powder coating — will strengthen vertical integration and enable seamless transfer of proven manufacturing processes across Schivo locations. Mexicali serves as a strategic transfer and scaling site to expand capacity, reinforce supply continuity, and accelerate customer growth trajectories.

Berlin, Connecticut

2,500 sq. ft.

Berlin is a specialized R&D facility focused on rapid-response development of precision fluid-control devices and systems. Working closely with OEM partners, AFP Berlin designs and prototypes next-generation fluidic solutions, accelerating engineering cycles and mitigating risk in product launches. Once validated, designs transfer efficiently to the most suitable Schivo manufacturing site for scalable commercialization, ensuring continuity from concept through production.

Changzhou, China

8,000 sq. ft.

Changzhou is a strategic logistics and light-manufacturing hub supporting Schivo’s Asia-Pacific customers. The location provides warehousing, regional fulfillment, quality control, and technical sales support for responsive customer engagement and streamlined execution. Integrated with Schivo’s global engineering and manufacturing network, the site strengthens end-to-end supply continuity and regional access for molded, machined, and assembled components.

Botterens, Switzerland

64,000 sq. ft.

Formerly Mecaplast SA, this precision molding center of excellence specializes in robotic-assisted and minimally invasive surgical components. The site delivers advanced clean-room injection molding, including overmolding, sterile molding, and sterile packaging to produce assemblies ready for market release. The facility builds tooling in-house to shorten development cycles and accelerate launch readiness and extends beyond polymer processing with metal and ceramic injection molding. Seamless integration with Schivo’s broader manufacturing network enables scale-up into full assemblies and value-added production beyond molding.