Value-Added Services

Schivo offers in-house, value-added services that go beyond typical contract manufacturing solutions.

Schivo offers a wide range of value-added services

Kitting: Schivo assembles and packages individual components or instruments into ready-to-use kits for OEMs and healthcare providers. These kits are often customized for specific procedures or use cases, helping streamline clinical workflows, reduce handling errors, and improve sterility and efficiency. Schivo can package kits in clean room or white room environments with blister packs, pouches, rigid trays, or clamshells. Medical device kitting includes a variety of products such as surgical instruments, implants, tubing, connectors, gloves, labels, and instructions for use.

Packaging: Schivo offers single-barrier and sterile-barrier packaging technologies that keep products sterile and protect them from damage during shipping. We can package any type of component — from a single plastic part to complex assemblies to complete kits containing multiple components.

Our packaging comes in a variety of form factors, including:

- Blister packs and thermal forming

- Soft blisters and pouches

- Rigid blisters

- Primary and secondary packing

Our safe and aesthetic packaging process includes in-house industrial cleaning, ultrasonic cleaning lines, and hot and pad printing. Our customers now can receive fully finished products — packed in their own cartons, labeled, and sterilized — ready for immediate use in their operating rooms.

Supply chain: Schivo helps simplify the OEM’s supply chain with value-added pre-production and post-production services. These include raw material and component procurement from qualified vendors prior to production and assembly. Plus, warehousing and logistics, inventory control, and lot tracking of finished products to OEMs and distribution networks.

Sterilization management: a critical component of regulatory compliance, product safety, and patient health, Schivo offers comprehensive planning, execution, monitoring, and documentation of sterilization processes to ensure that medical devices are free from microorganisms before customer delivery. Our process validation includes IQ/OQ/PQ methodology that ensures consistent sterility assurance levels.

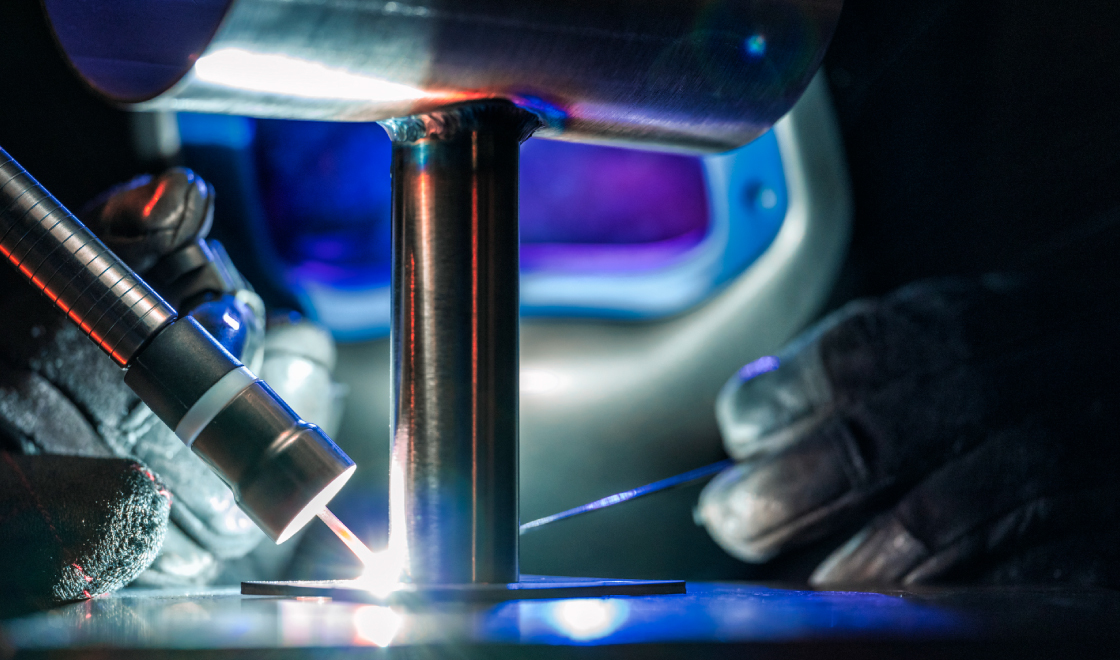

Precision tungsten inert gas (TIG) welding: Schivo’s precise, clean, high-quality welding process is frequently used in medical device manufacture, especially for components made from stainless steel, titanium, and other biocompatible metals. Schivo’s highly precise TIG welding is essential for producing surgical instruments and implant components. Our process maintains biocompatibility, prevents distortion in thin-walled parts, and produces strong, corrosion-resistant welds.

Brazing: This precision joining process assembles metal components by melting a filler metal with a lower melting point than the base materials. Schivo’s brazing process creates strong, hermetic, and biocompatible joints without melting or deforming the associated components.

Soldering: Schivo’s precision joining technique is used to connect components in electronic assemblies and certain mechanical joints within medical devices. Our soldering systems precisely control temperature to avoid damaging sensitive components. This clean soldering technology ensures adhesion and prevents corrosion. Microscopic and X-ray inspection are used for quality verification.

Robotic sharpening: Schivo provides the automated precision sharpening of components such as surgical blades, hypodermic needles, trocars, cannulas, and other cutting instruments. This automated process ensures consistent sharpness, geometry, and surface finish—critical for safety, efficacy, and regulatory compliance. Schivo’s robotically controlled sharpening systems follow programmed paths with micrometer-level accuracy, ensuring edge profiles, finishes, and tip geometries remain identical from part to part. High-throughput automation has integrated quality and contamination control for traceability, clean room processing, and regulatory compliance.