Fast and Consistent Communication

As a supply chain manager in the medical devices industry, you understand the importance of having reliable business partners that can deliver on time, while maintaining the highest level of quality. Fast and consistent communication from a single point of contact is also critical to a relationship with any supplier.

At Schivo, we provide frequent updates about the production process and shipment of orders. We know that as a supply chain manager, you rely on your partners to anticipate the next task and to be able to forecast 3-4 years in advance. That's why we have developed a system to provide you with real-time updates on our capabilities and inventory levels. This allows you to plan ahead and make informed decisions about your supply chain.

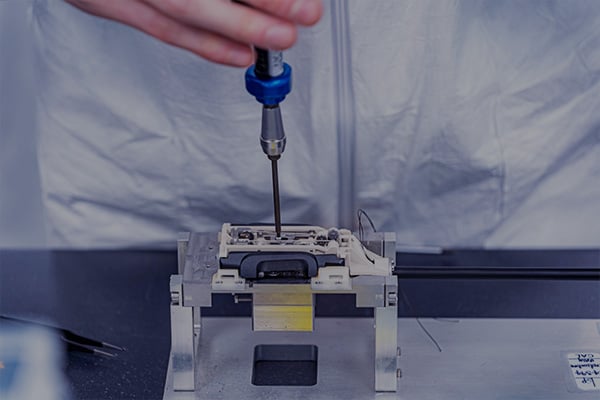

Our team of experts are dedicated to staying ahead of industry trends and predicting future demand for components, assemblies, and sub-assemblies. We work closely with our customers to understand their needs and to ensure that we have the necessary resources in place to meet those needs. With Schivo as your partner, you can trust that your supply chain will always be one step ahead.

Schivo is committed to delivering on-time with 97-98% positive delivery rates. We are also dedicated to meeting the standards of our customers. We have Disaster Recovery policies in place and comply with annual customer audits and FDA standards. Additionally, we are ISO 13485 certified, meaning we comply with international standards for medical device quality management systems.

A Proactive and Flexible Partner

You likely also require highly detailed documentation of every step of the manufacturing process. Our thorough records enable us to track and improve our performance over time via application of kaizen and Lean Production principles. Our low failure rate is a testament to the effectiveness of our process documentation.

However, emergencies happen, which is why we have the capacity to make room for unexpected orders and support a 3-5 business day turnaround. We are always prepared to respond quickly to our customer's needs. Our customers can also count on our dedicated point-of-contact to be available 24/7 and answer their personal mobile phones if necessary, ensuring that they always have access to the information they need, when they need it.

As a supply chain manager, you are probably constantly wondering when deliveries will come in. Long lead times have made you look much further ahead than before, and the pressure from multiple areas of your organization can create significant stress. By partnering with Schivo, you gain a proactive supplier that plans ahead, collaborates, and communicates clearly, consistently, and effectively, ultimately mitigating your stress levels significantly. We are committed to working together with you as a partner, not just a vendor, to find the best solutions for your supply chain needs.