Design Methodologies

Design for Manufacturing (DFM):

Schivo works with clients in the early concept stage, linking design directly to manufacturing to ensure an efficiently designed and engineered product. Using the Design for Manufacturing (DFM) approach and performing early run pilot manufacturing builds, our engineers can identify discrepancies, prevent mistakes, and optimize product design from the start. The result is a simplified design that reduces cost of goods sold (COGS), accelerates time to market, and assures reliability, compliance, and quality standards.

Design, Measure, Analyze, Improve, Control (DMAIC):

We think beyond the initial project. Dedicated to continuous process improvement, our highly trained team works under the Six Sigma management philosophy to ensure we get the component right and are prepared to address any long-term needs and potential challenges. Using the Define, Measure, Analyze, Improve, Control (DMAIC) methodology, we can more quickly identify the root cause of an issue, develop solutions for it, track results, and refine processes to improve product and business performance.

Bespoke Testing

From early-stage innovators needing a quick prototype to industry leaders with technically complex parts and assemblies, our team works with you in designing a customized testing regiment that delivers accurate, repeatable products and meets the most stringent regulatory requirements. With extensive capabilities and technologies, including standard metrological techniques, coordinate measuring machines (CMM), and advanced vision inspection systems, Schivo routinely develops product-specific inspection and verification methods to meet your unique needs.

Certifications & Training

At Schivo, we believe the most critical factor to success is investing in the training of our team. Current training initiatives include, Six Sigma courses, SEAM’s Additive Manufacturing training, and an 18-month Engineer Career Entry Program for recent graduates. We have also developed our own Four Quadrant Milling program to ensure Schivo is producing machinists of the highest quality across multiple milling machines. Certifications: ISO 13485, In-house Six Sigma Greenbelts & Blackbelts, FDA & CE Registered, EUMDR.

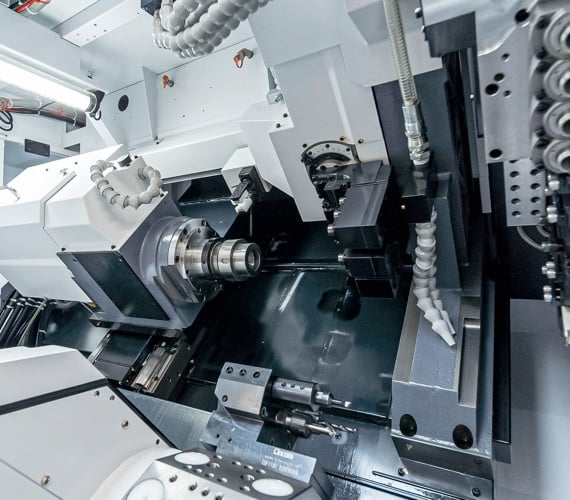

Technologies & Tools

From 3D CAD and Finite Element Analysis software to our Programmable Logic Controller, Schivo provides exact virtual concepts to validate performance prior to manufacturing and seamlessly integrates electrical capabilities. 3D Additive Manufacturing technology enables computer-generated models to be quickly prototyped via our in-house 3D printing department. And our Cyber-Physical-Systems leverage automation through deeply integrated systems and physical components. By utilizing the right technology and tools, Schivo reduces design iterations, time, and cost in reaching a final design.